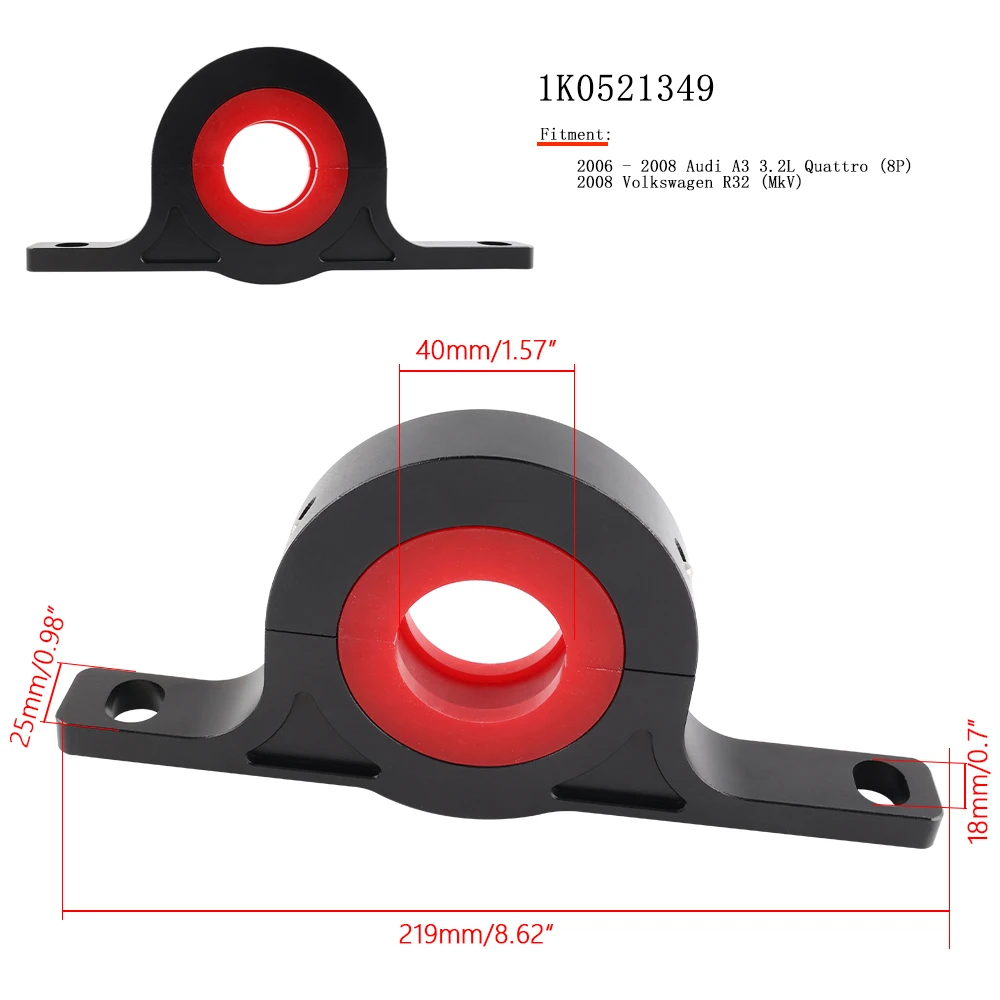

SPECIFICATIONS

Brand Name: One Direct

Hign-concerned Chemical: None

Manufacturer Part Number: 014209la01KT

Material: Billet aluminum carrier housing assembly

Model Number: bbs008

OEM NO.: 1K0521349

Reference numbers for other associated a: 1K0521101J 1K0521101H

Type: Driveshaft Center Support Bearing Brace

car fitment 1: 2006 - 2008 Audi A3 3.2L Quattro (8P)

car fitment 2: 2008 Volkswagen R32 (MkV)

fitment: FOR VW MK5 R32/MK6 Golf R & Audi 8p A3

material: Polyurethane bearing support

product name: replacement Driveshaft Center Support Bearing

replace number: 1K0521349

tuning parts: Billet aluminum carrier housing assembly

Driveshaft Center Support Bearing Brace for VW MK5 R32/MK6 Golf R & Audi 8p A3

This new driveshaft support center bearing is designed to fit the 8P Audi A3 3.2L Quattro & MkV Volkswagen R32. We manufacture this replacement unit in-house specifically for this application.

Ideal for fixing issues commonly caused by a failing driveshaft support, including vibration at certain speeds and loud noises coming from the driveshaft tunnel.

Fitment:

2006 - 2008 Audi A3 3.2L Quattro (8P)

2008 Volkswagen R32 (MkV)

-

Carrier Bearing Bushing:

durometer polyurethane bearing support clamps on over existing center support bearing

Fully replaces worn-out rubber that allows for excessive driveshaft movement

-

Carrier Housing:

6061-T6 billet aluminum support brace properly constrains the polyurethane bearing support to the driveshaft bearing

Type II black anodized for corrosion protection

Includes new carrier mounting hardware, flex disc hardware and thread locking compound needed for installation

Retains factory mounting location and exhaust clearance

KIT CONTENTS

Polyurethane bearing support - 2 halves

Billet aluminum carrier housing assembly

0.5ml Medium strength threadlocker

Carrier housing assembly hardware

New TTY hardware to install the carrier housing to chassis along with front and rear flex disc coupling hardware

PRODUCT DEVELOPMENT

Our ECS Driveshaft Center Support Bearing Brace was designed, engineered, tested and quality inspected by our Research and Development team in our Wadsworth, Ohio facility. We strive for the highest level of precision and quality through leading-edge product development technology including FARO laser scanning for reverse engineering and quality inspection, SolidWorks 3D CAD modeling, rapid prototyping utilizing our in-house 3D printer, and rigorous long term product testing.

INSTALLATION AND SUPPORT

Need installation tips? We put together a full installation tutorial from start to finish including how to remove your OEM parts in detail! See our Installation PDF under the INSTALLATION Tab for more information.

Installation is possible with the driveshaft still bolted in, however, for ease of access we recommend removing the driveshaft completely.

As with any driveline upgrade you should expect a minimal increase in NVH (Noise, Vibration and Harshness) while under load and at highway speeds.

1K0521349